ઉત્પાદન વિગતો

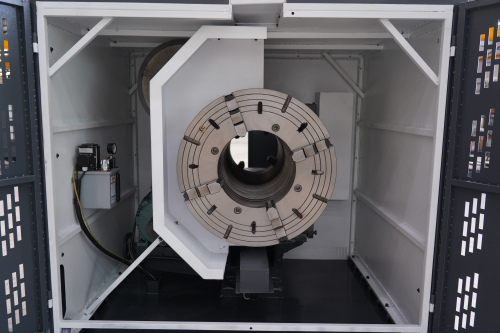

CNC Big Bore Lathe Machineis suitable for Turning, Threading of all kind of cast iron or steel components. Our offered machine is used for Machining and Drilling work in various industries.Specifications:

- Maximum Turning Diameter: 200mm to 1600mm

- Spindle Size: A2-5 to A2-15

- Distance Between Centers: 300mm to 3000mm

- Max Bar Capacity: 25mm to 350mm

- Bore Through Spindle: 25mm to 350mm

Exceptional Machining CapacityThe BIG BORE CNC Lathe Machine boasts a large swing over bed and cross slide, supporting heavy and oversized workpieces. Its bore diameter capacity reaches up to 500 mm, making it ideal for pipe machining and industrial metalworking tasks. With precision features, including 0.01 mm positioning accuracy and automatic centralized lubrication, it delivers reliability even during extended operations.

Advanced Automation and ControlsIntegrating PLC control and leading CNC interfaces from Fanuc or Siemens, the machine streamlines operations for maximum efficiency. The 4-position electric tool turret, variable spindle speeds up to 1000 rpm, and RS232/Ethernet connectivity offer adaptability to complex jobs. Its fully automatic functions and computerized control enable consistent repeatability, critical for high-volume production.

FAQs of BIG BORE CNC LATHE MACHINE:

Q: How does the BIG BORE CNC Lathe Machine achieve high precision in heavy-duty applications?

A: The machine uses a monolithic one-piece bed, hardened and ground guideways, and an AC Variable Frequency Drive to minimize vibrations and maximize stability. Its automatic centralized lubrication and Fanuc/Siemens controllers ensure positioning accuracy up to 0.01 mm, with repeatability of 0.005 mm, ideal for industrial-grade precision turning.

Q: What types of materials can be processed with this lathe machine?

A: The BIG BORE CNC Lathe Machine is designed to handle cast iron, steel, and similar heavy metals efficiently. Its robust structure and high rigidity allow for accurate machining of large-diameter pipes, metal rods, and complex components, suitable for a range of industrial fabrication processes.

Q: When is it advantageous to use the optional bar feeder with this CNC lathe?

A: The optional bar feeder is most beneficial during high-volume or continuous production runs that require automated workpiece feeding. It enhances workflow efficiency, reduces manual intervention, and maintains production consistency, especially when machining long bars or pipes.

Q: Where is the best environment to operate this machine?

A: This CNC lathe is optimized for heavy workshop environments such as manufacturing plants, metal fabrication facilities, and industrial pipe machining centers. Its sturdy build and high power consumption (12 kW) make it suitable for settings where heavy-duty and precision machinery is required.

Q: What is the process for customizing the machines controller brand and table size?

A: Customization is available for the controller (Fanuc or Siemens) and the table size. Customers can specify their requirements to the manufacturer or dealer during the procurement process. The technical team configures the machine according to client specifications, ensuring seamless integration and optimal performance.

Q: How does the integrated coolant and lubrication system benefit machine operation?

A: The integrated coolant system keeps both the workpiece and tooling at optimal temperatures, reducing thermal distortion and extending tool life. Automatic centralized lubrication ensures consistent oil flow across critical machine axes, preventing wear and promoting smoother, long-term operation.

Q: What safety features are included with the BIG BORE CNC Lathe Machine?

A: The lathe machine is equipped with essential safety measures, such as an emergency stop button and overload protection system. These features help prevent accidents, protect both the machine and operator, and ensure safe shut-down during unexpected events or operational anomalies.